Uses and Instructions

Constructing a plumbing system for ships and plants requires extensive experience and knowledge, and currently the industry is heavily reliant on experienced workers.

At Plus One Techno Co.,Ltd., we are currently researching and developing a new technology called Pipe Form which does not rely on experience to fabricate various pipes.

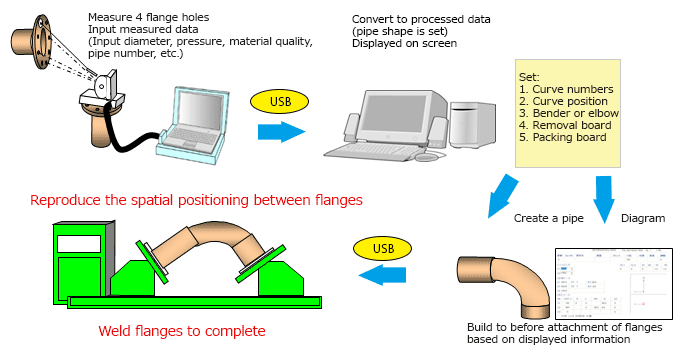

Pipe Form is composed of accurate measuring components which 3-dimensionally analyses the worksite and converts measurements into data, fabrication software, and components which recreate the worksite’s dimensions for precise fabrication. Through this technology, we aim to increase quality by manufacturing products specific to the site and specifications safely and efficiently.

Building a New Ship

| By fabricating structural pipes exactly to specifications and by fabricating connecting pipes per requirement off-site, simplify the construction of plumbing systems. Pipe Form can be utilised in fabricating both structural and connecting pipes. The most difficult aspect of pipe fabrication is to correctly calculate the spacial dimensions between flanges. In other words, the distance between flanges, the angles, and the perforations on the flanges require absolute precision. |

|

Structural Pipes

Pipe Form 3-dimensionally analyses the layout between flanges on existing structural pipes, creating data for reproduction. The reproduction Instrument then takes the data and reproduces a pipe with accurate spacing between flanges, flange angles and perforations exactly to specifications. By placing a flangeless pipe onto the reproduction machine, it will then weld on flanges to create a finished structural pipe.

Connecting Pipes (Pre-existing, Molded)

3-dimensionally analyze re-existing pipes on-site with measurement Instrument, calculating spacial dimensions. From the gathered data, create a blueprint.

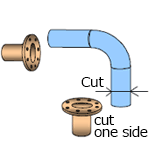

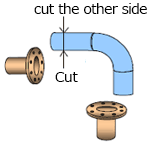

Conventional Fabrication Procedures (Pre-existing pipes)

|

|

|

||

| Prepare a longer pipe | ||||

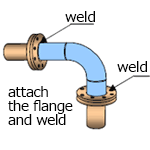

Conventional Fabrication Procedures (Molded pipes)

|

|

|

|||

| Bolt and weld the flanges together, fabricate a cast-pipe | Remove cast pipe, then transport to pipe factory. | Attach flanges to cast-pipe, weld reinforcing materials, remove cast-pipe. Measure distance between flanges and create blueprints | |||

|

|

|

|||

| Attach flanges to cast, insert pipe, weld, and remove. After welding flanges, product is complete. | Connect pipes accordingly to the blueprint | Draw a blueprint, calculate dimensions for processing (cut dimensions, bending angles, etc) |

|

|

|

|||

| Measure the 4 dimensions of the flange holes. (Diameter, quality, flange pressure, pipe number) | Weld the output flange of the pipe processing data conversion diagram. (1) Set the number of curves in the straight pipe : 2 curves. (2) Set the turn position. (3) Select the bender or elbow (4) Set the flange taper. (5) Set the packing fee. |

Pipe diagram | |||

|

|

|

|||

| Weld the flange for completion! | Use reproduction equipment to return it to its original state. Insert the flange and weld it to complete the work. | Assemble pipe with diagram measurements and weld. |

For ship repair

Repaired pipes can be fully restored on-site

Pipe Form also functions perfectly with repaired ships.

Pipe Form will analyze the flanges within the work site, 3-dimensionally analyze and calculate spatial dimensions, and create a blueprint from the gathered data. The reproduction Instrument will then produce a flangeless duplicate accurate to specifications. By inserting the flangeless pipe into the reproduction Instrument, it will then weld on the flanges to complete a structural pipe.

Measuring and Recreating Repaired Pipes (Conventiona Method)

|

|

|

||

| When a pipe needs to be repaired | Remove pipe, then transport to pipe factory | Weld on flanges with reinforcement materials on a surface plate |

Suggested construction method

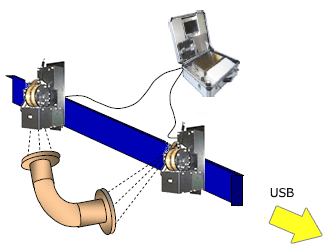

1. Factory measurementA method to remove the pipe and measure it in the factory, etc. After measuring the 4 flange dimensions on one side, move the measurement instrument, and finish measurement of the 4 flange dimensions of the other side. |

|

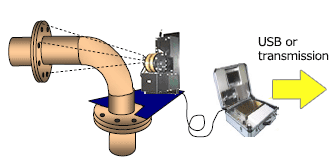

2. Ship interior measurementA method to remove the pipe and measure it in the factory, etc. |

|