Petit Scale Functions

Petit Scale Series is a Pipe-Feeder-Attached Automatic Weighing System (Weighing Unit) that satisfies the needs of all weighing and packing industries. Thanks to its high-speed and high-performance weighing system (weighing unit), Petit Scale Series has made it far easier to conduct a small-quantity weighing of instant noodles, health foods, seasonings, tablets and other medicines, tealeaves, powders or others items.

Petit Scale Series is a Pipe-Feeder-Attached Automatic Weighing System (Weighing Unit) that satisfies the needs of all weighing and packing industries. Thanks to its high-speed and high-performance weighing system (weighing unit), Petit Scale Series has made it far easier to conduct a small-quantity weighing of instant noodles, health foods, seasonings, tablets and other medicines, tealeaves, powders or others items.

It is unfortunate that currently, many factories use a parts-feeder system (a vibrating system) to charge ingredients or materials onto a bucket conveyor, but without conducting proper weighing beforehand. This does not enable workers to conduct precise weighing of materials in advance, and thus results in major waste in production processes.

Our Petit Scale Series has adopted a self-developed Pipe-Feeder System (our patented technology). Materials are clipped out in a uniform quantity by Pipe-Feeder System, and those materials go through the automatic weighing, mixed weighing or quantity measuring of our weighing system. Thus materials are divided into a preset uniform quantity in a high speed and weighed efficiently

Dried vegetables (dried peas, dried hot peppers, etc.)

Cut vegetables, healthy foods, dried foods, sugar and other seasonings, condiments, chopped dried seaweed, pasta, green tea leaves, other types of tea leaves, powdered soup, coffee, instant foods, seeds, pellets, snacks, cereals, tablets, pills and other types of foods or materials which needs to be divided into a small quantity.

Our weighing system also accepts frozen items, wet or fatty items and other various types of materials.

Any inquiry is welcome. We are ready to offer brochures and price estimation.

Feel free to contact us.

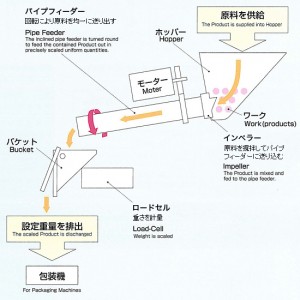

How Petit Scale Works:High-Speed & High-Accuracy Weighing System

Product materials (or works), after being stocked in the hopper, are agitated by the impeller, and then the agitated works go to the pipe feeder. Pipe Feeder rotates and clips the works out in a uniform small quantity.

The clipped works go down into the bucket and are weighed by the load-cell

When the total load of the works reaches the preset weight, the clipping function stops.

|

When the bucket receives the discharge signal, the bucket opens to discharge the works. This operation process is repeated |

Comparison with conventional Parts-Feeder System

| Conventional Parts-Feeder System | Petit Scale | |

|---|---|---|

| Works Charging Line |

|

|

Comparison between Petit Scale and Other Systems

| System Type | Advantages | Disadvantages |

|---|---|---|

| Petit Scale |

|

|

| Parts-Feeder |

|

|

| Gauge-Measuring |

|

|

| Computer Scale |

|

|